Refrigeration and freezing stores and their importance

Refrigeration and freezing stores have become necessary products, especially in recent years due to the recent developments taking place in the country, such as the construction of many commercial units. Thus, the trend of owners of shops, factories, and malls to refrigerate and freeze stores has become necessary, because they help them store food items that need low temperatures to protect them from the changing weather factors that lead to the destruction of food products.

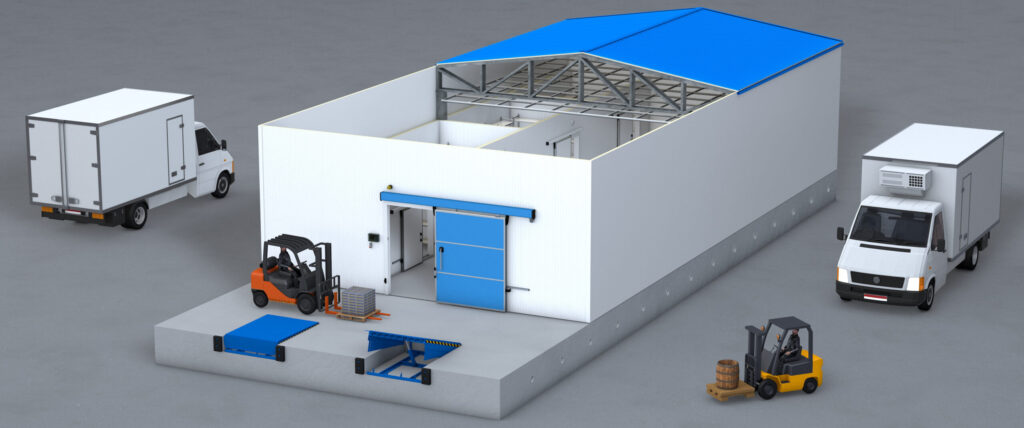

Egypt for Panel and Steel Industries ″PSI″ makes the cooling and refrigeration warehouses the most efficient. We care about all the parts and details, starting from ceilings, walls, floors, and even iso-thermal doors to ensure the best quality and performance for maintaining the stored products.

Cooling stores

Egypt for Panel and Steel Industries ″PSI″, manufactures the Sandwich Panel which is used in the construction of refrigeration and freezing rooms or large blocks that are made specifically for storing and keeping products at low temperatures and preventing the diversion of normal temperatures to the refrigeration and freezing stores. It also prevents the leaking of cold from the refrigeration and freezing stores to the outside, where food, vegetables, fruits, and meat are stored. Refrigeration and freezing stores are located in many places such as ports, places close to ships, hypermarkets, restaurants, hotels, fish farms and some agricultural lands, and commercial malls, where goods and products that are imported are stored to keep them from getting damaged and to make sure it stays fresh.

Refrigeration and freezing stores are their importance

The industry for refrigeration and freezing storage is one of the most important — to keep food products from getting rotten and to store them in cold and freezing stores at low temperatures to keep them as long as possible.

The cold room industry started about 40 years ago in the United States, where it started to conserve meat and then it spread to Europe, where temperatures are very low and snow is spreading, and they used sawdust and ice to conserve food, so the sawdust was the thermal insulator, which kept the ice from melting for a longer period of time, helping to conserve the goods stored in the cold and freezing rooms for a longer period.

Then, as technology progressed, air circulation and distribution fans were used to make refrigeration and freeing stores until we moved into the mechanically cooled refrigeration and freezing stores industry, and finally, in the modern era, the refrigeration and freezing stores industry became dependent on cooling units that operate by electricity.

Refrigeration and freezing store types

There are two types of refrigeration and freezing stores, and they are different in use

1- Cold rooms for materials used in production lines

This type of refrigeration and freezing store is built near production centers where materials used in food processing or other industries are stored.

2- Cold rooms for materials used in distribution:

This type of cooling store is used for the purpose of keeping products for a shorter period of time until the stored products are distributed or sold and the cooling store is available for distribution most of the time in malls, supermarkets, and hotels.

Cooling stores are also divided into two types based on storage temperatures:

There’s also another classification of refrigeration and freezing stores based on temperature

- Refrigeration stores operate at a temperature above freezing point.

- Refrigeration stores operating below freezing temperature.

Dimensions and prices for refrigeration and freezing stores

The dimensions of the refrigeration and freezing stores are determined by the size and quantity of products to be stored in the cold store or cold room. For example, when 10 tons of frozen foods are stored, you may need a room of 30 cubic meters, which is a significant factor in calculating the price of the refrigeration and freezing store. Other factors influencing the price of refrigeration stores and freezing rooms are the thickness of the sandwich panel used and the amount of square meters used for in the construction of the cold room.